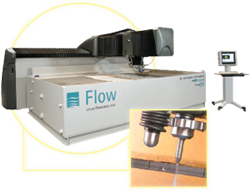

Waterjet Cutting

Waterjet Cutting

- Flow Integrated Floating Bridge 6012

- 94,000psi Hyperjet

- Dynamic Water Jet Cutting Head

- Ultra Pierce Technology

- Table Size is 4 meters (13.12 feet) X 2 meters (6.56 feet)

Capabilities

Flow Waterjets enable us to cut a variety of applications with ease.

- Material thickness from 1/16 inch (1 mm) to over 8 inches (200 mm) thick into any shape in a single step.

- With water only Waterjet can rapidly cut soft materials such as plastic, rubber, cork, and foam.

- With abrasive Waterjet can cut hard materials such as steel, stainless steel, aluminum, titanium, and stone with no heat-affected zone and superior edge quality.

- Utilizing ultra pierce technology Waterjet can cut brittle materials including glass, laminated glass, G10, Kevlar, ceramics, and composites without de-lamination. We can put very small holes in these brittle materials which is not possible with standard Waterjets.

Benefits to the customer

Our 94,000 psi, water jet with Dynamic cutting head, and Ultra Pierce Technology only available from Flow give us an advantage in speed and quality that we can pass on to you

- 20-30% lower part cost than 60,000 psi systems

- Increased speeds that are 20-30% faster than 60,000 psi

- Increased power, density, and jet efficiency

- 40% higher velocity

- Lower abrasive consumption by 30-50% les abrasive than 60,000 psi

- Dynamic Water jet virtually eliminates taper; taper is < 1 degree in straight-line geometry

- Active Tolerance Control produces more accurate parts at significantly higher cutting speeds than parts cut with a conventional water jet

- Tolerance is +/- .003 on some materials which can reduce or even eliminate machining